Sites across construction, mining, aviation, energy, and logistics demand fast, flexible solutions for vertical access. Well‑designed temporary stairs (sometimes called a temporary staircase or portable stairs) delivers a practical solution:

- Easy assembly in under 20 minutes—no structural steel scaffold bay required.

- Full stair rail systems with a compliant upper surface of the handrail 1 m above the tread surface.

- Adjustable legs maintain correct riser height, tread depth, and vertical rise.

- Built from solid aluminium material, so there are no hidden manufacturing defects.

Key point: When the only alternative is ladders—whether step ladders, fixed ladders or improvised job‑made ladders—temporary stairs cut fall risk by 70 % and keep foot traffic flowing.

Introducing AdjustaStairs – Lightweight, Adjustable, Temporary Stairs for All Industries

For projects that demand rapid deployment and rock‑solid safety, our AdjustaStairs system assembles in minutes, meets BS EN 12811‑1, and adapts to every site—from high‑rise construction to excavation access.

AdjustaStairs: Temporary Staircases for All Industries

From modular construction and residential high-rises to remote mining operations and logistics depots, the AdjustaStairs system adapts to your site conditions. Lightweight, compliant, and fast to deploy, AdjustaStairs are trusted by professionals across:

| Construction | Interior Fitout | Energy |

| Mining | Defence | Aviation |

| Transport & Logistics | Industrial Manufacturing | Facilities & Maintenance |

Temporary Stairs vs. Scaffold Towers & Ladders

| Feature | Temporary Stairs (e.g., AdjustaStairs) | Scaffold Stair Tower | Ladders |

|---|---|---|---|

| Install / removal | Easy assembly: 1 flight in 15-20 min | 2-3 hrs plus scaffolders | 5 min but limited height |

| Supporting structure | None | Full scaffold bay (structural steel) | None |

| Weight | 45-65 kg per flight | 250 kg+ | 15 kg |

| Capacity | High foot traffic (+ emergency personnel) | High | 1 user |

| Compliance | Meets the following requirements of Sections BS EN 12811-1 & WAHR | Design check (TG20/SG25) | Often fails WAHR |

| Cost (3-month hire) | £380 | £1,100 | £60 but poor productivity |

Typical Use Cases

- New builds while the permanent staircase cures or is installed.

- Existing buildings under refurbishment where the stairs are demolished.

- Bridge or culvert work where only metal pan landings are in place.

- Emergency egress routes for shift work and emergency personnel.

Wherever there’s repeat foot traffic and work area segregation, temporary stairs excel.

Standards & Compliance

- BS EN 12811‑1 – performance for temporary works equipment.

- Work at Height Regulations 2005 – hierarchy insists on stairs over ladders if feasible.

- TG20 & SG25 – scaffold design guidance if you go the stair‑tower route.

- HSE Ref: STAIRS/03 stipulates max riser height 220 mm and min tread depth 220 mm.

- The upper surface of the stair rail must sit 900–1,000 mm above the nose of the treads of the stairs, with top rail supports every 2 m.

Adjustastairs: Specifications

| Parameter | Range / Spec |

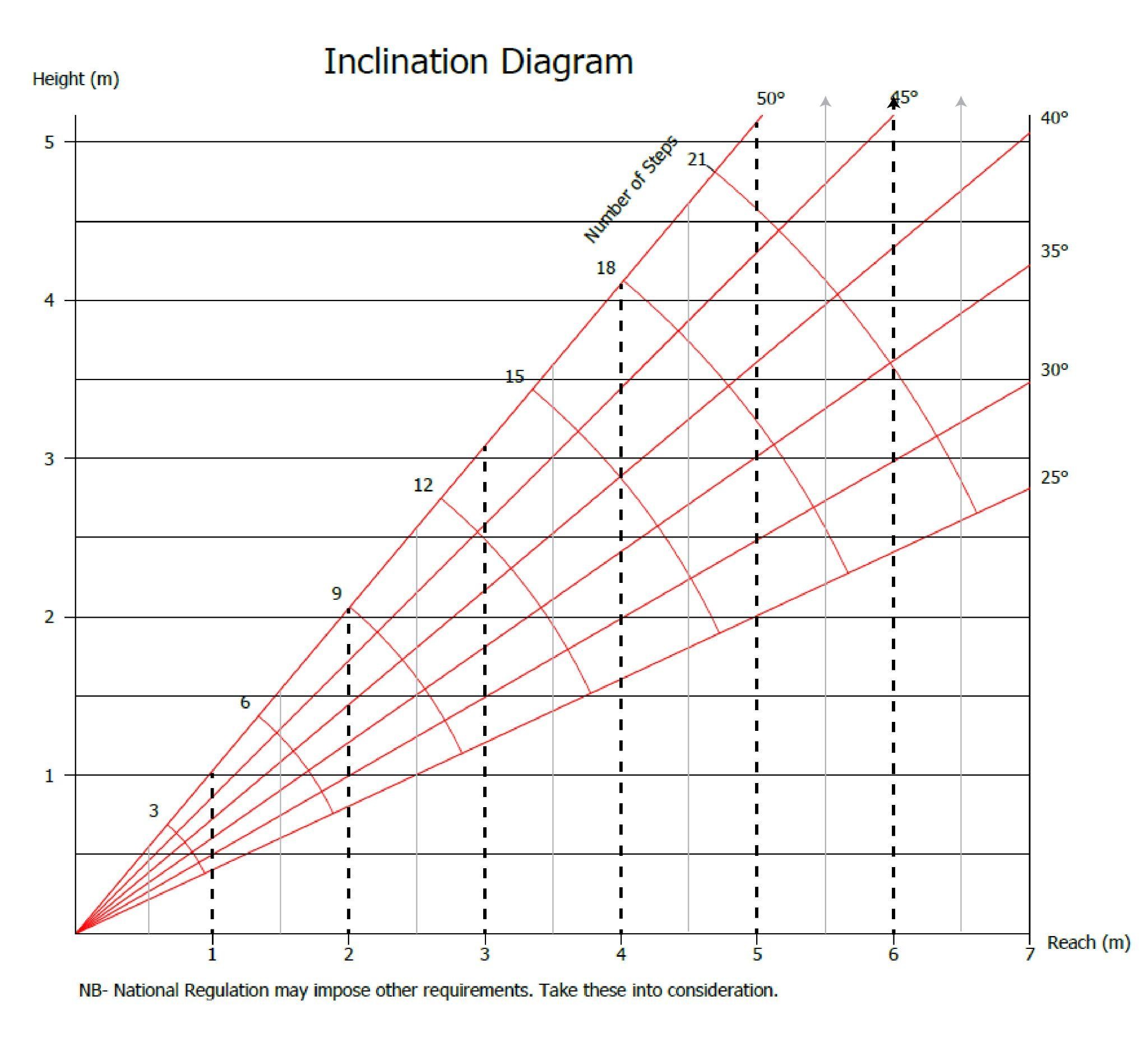

| Vertical rise per flight | 600 mm – 3,500 mm |

| Full width between handrails | 600 mm / 800 mm options |

| Riser height | 200–220 mm |

| Tread depth | 240 mm |

| Stair rails material | 6061‑T6 aluminium (solid material) |

| Loading (Construction workers + tools) | 2.0 kN/m² |

Compatibility

- Hooks onto concrete, structural steel or timber landings.

- Works with plywood or metal pan landings.

- No biscuit jointer‑style timber joints. Everything is bolted aluminium for maximum strength and durability.

Installation: 7 Quick Steps (Easy Assembly)

- Remove the packaging and lay the stair flat.

- Place the stair on the support surface with the top step facing the fixing location.

- Open the stair treads by twisting steps, to minimum of 30-degrees.

- Lift the handrails until the locator-tab can be slipped over the bolt, and tighten the wing-nut firmly.

- Secure the locking tab position by tightening the lock tab knob.

- Fix the top step onto the support rail, floor, or beam.

For timber, use a hex washer type 17 (14 gauge) x 50mm screw to secure it into a timber base.

For concrete, Use a 10 x 50mm concrete anchor screw. The concrete must be a minimum of 25MPa.

Where possible, fix the foot of the stair onto the lower support surface

⏱️ Average time: 18 min, two operatives, zero power tools.

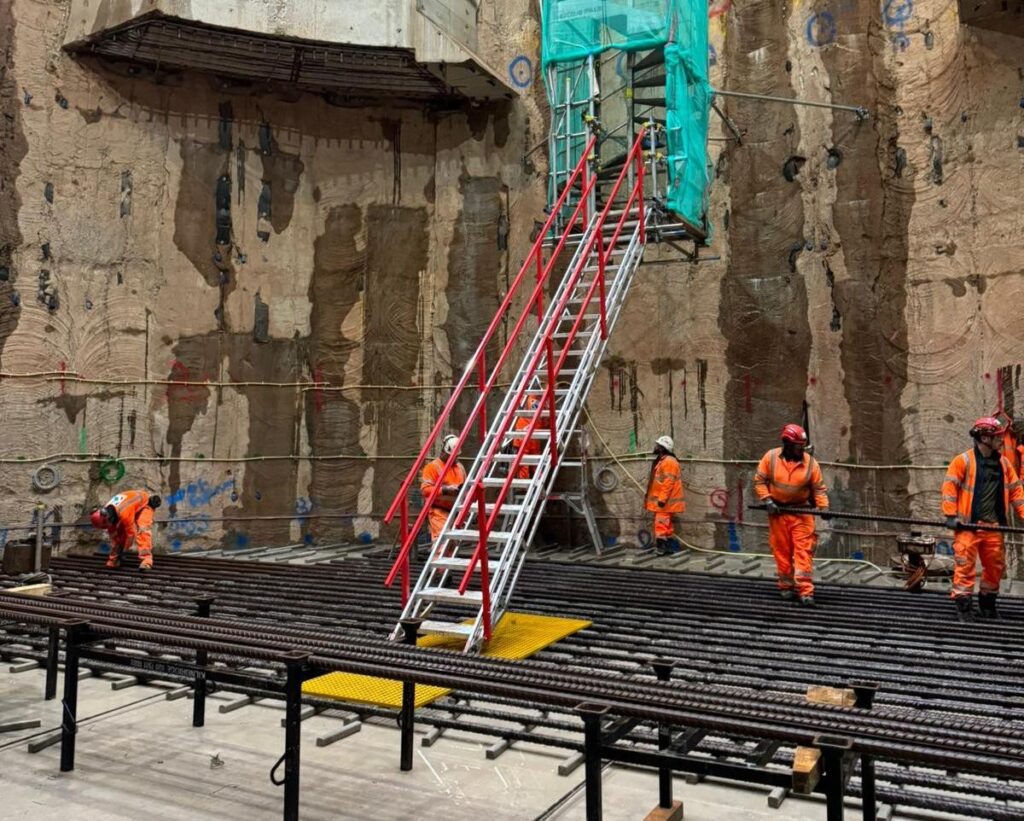

Case Study: Double-Width Stairway to Success: SafeSmart Elevates Mace’s Safety and Efficiency

In large scale construction projects, every minute counts, and ensuring worker safety is paramount.

Identifying the Challenge

For Mace, the challenge was clear; downtime was becoming a significant issue with workers frequently forced to take longer, indirect routes to reach their work zones, leading to lost productivity. In addition, Mace required a dependable emergency route that complied with stretcher access requirements so that workers could be safely and promptly evacuated in the case of an emergency.

Supplying the Solution: Double Width AdjustaStairs and Landing

With our renowned Double Width AdjustaStairs, and secure mid-landing that allows for two-way traffic and emergency stretcher access, SafeSmart was able to overcome the challenge. This innovative solution allowed workers to move efficiently between levels, cutting down on travel time, while ensuring safety regulations were followed.

The Result: A Transformation in Safety and Efficiency

SafeSmart’s solution had an instantaneous and significant impact.

Mace now have a quick and compliant emergency route, capable of accommodating stretcher access in case of an emergency. Equally as important, workers are now saving valuable time every day by taking the more direct route provided by the AdjustaStairs

Temporary Staircase FAQ’s

Ready to replace ladders with a safer, compliant stair system? Request a quote or call +44 (0)845 382 1000

Yes, please get in touch with our sales team in order to find out more.

Yes—2.0 kN/m² loading covers crews, tools and inspectors.

Yes — we offer both 600mm and 1200mm wide AdjustaStairs. The 1200mm option is specifically designed for emergency stretcher access and allows for two-way foot traffic at all times, making it ideal for high-activity worksites or where rapid evacuation is a consideration.

Guard with fire blankets where hot works cross the work area.

Visual check weekly; full strip inspection every six months.

Yes unless the stair abuts a wall; then guard the unprotected side only.

- Direction of travel on a ladder is near‑vertical, increasing fatigue.

- Only one worker moves at a time—delays multiply over weeks.

- In slippery conditions, the accident rate is 4× higher than on stairs.